In 2017, a start-up announced a bold and simple plan: develop the world’s greenest battery cell and establish a European supply of batteries to enable the future of energy. Here is the story of Northvolt.

The verdict of the IPCC report in late 2018 was unequivocal: the world needs to act within 12 years in order to avoid catastrophe.

Six years previously, Peter Carlsson and Paolo Cerruti met at Tesla’s factory in Fremont, California. They had both recently joined the company to head up supply chain operations.

Peter had joined Tesla from NXP Semiconductors in Singapore, and before that Sony Ericsson in Sweden. He holds almost two decades’ experience working in manufacturing, purchasing and supply chain operations.

It was Peter who convinced Paolo to leave Paris and join Tesla in California.

Shortly after graduating in Aerospace Engineering Paolo began working at Renault-Nissan. He spent fifteen years with the company in France, Japan and India before joining Tesla.

Around this time, global industries were in a state of flux. Renewable energy was on the rise. Electric vehicles were becoming a competitive product. And electrification was sweeping across industries. Across it all, there was a common denominator – batteries.

Mapping the supply chain for the Tesla Model S, it became clear that battery cells were a critical strategic asset but that global supply wouldn’t come close to covering demand. Tesla took the decision to build its own battery factory – Gigafactory 1 – in Nevada.

Some 8,600 km away in Stockholm, Carl-Erik Lagercrantz and Harald Mix, who had jointly established the green-tech investment company Vargas, reached the same conclusion as Tesla.

Harald Mix is the co-founder of the private equity firm Altor. He was previously deputy CEO and co-founder of Industri Kapital. He holds a BSc from Brown University and an MBA from Harvard University.

Harald founded Vargas together with Carl-Erik Lagercrantz focused on enabling sustainable industry early stage investments.

Driving that demand for lithium-ion batteries are three key sectors: electric vehicles, energy storage and industrial applications.

Global battery demand by application

Carl-Erik Lagercrantz – Calle – is the Chairman of the Board at Northvolt. He holds the same position at Incell International. His background is within telecom and he has served as CEO for British Telecom Nordics and Baltics.

Carl-Erik decided to reach out to Peter, whom he had followed closely from Sweden, to discuss European battery production. What he didn’t know was that Peter was still in California, where it was 4 o'clock in the morning.

Part 2: Early Days

As the idea took hold, the small group began work on a pre-study.

Over the course of six months Paolo and Peter travelled the world to meet with potential customers, suppliers, politicians and other stakeholders, and to recruit a team.

One evening in fall of 2016, the decision was made: a European battery gigafactory would be built. Operating under the name of SGF Energy, the small group gradually began to grow into a hand-picked team of experts.

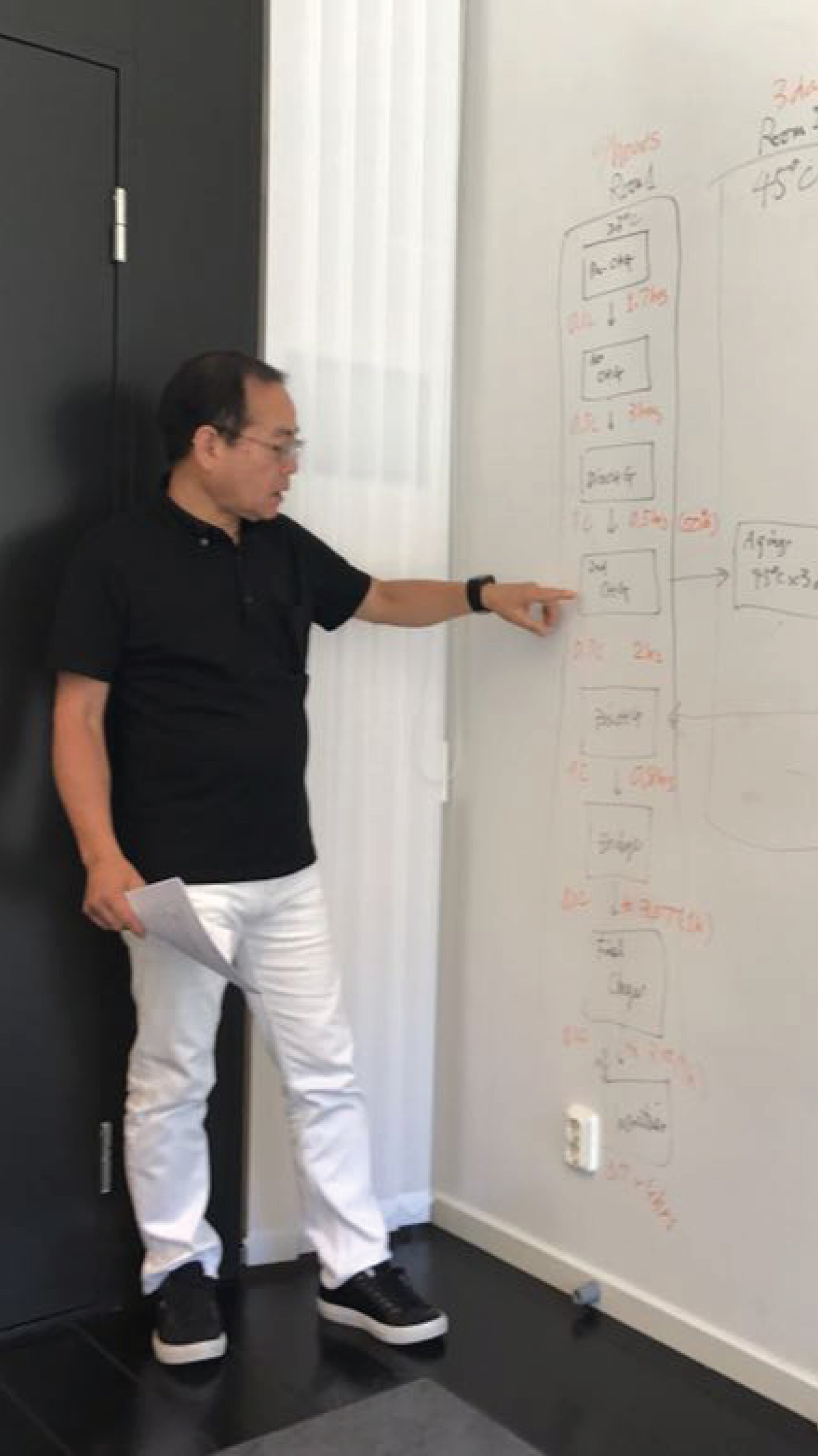

A key moment was the welcoming of Yasuo Anno – Anno-san – who moved to Stockholm from Tokyo to join the endeavour. He had spent several decades in leading roles within the Japanese battery industry, including at BASF TODA, Panasonic and Sony.

Anno-san would not only play a key role establishing Northvolt’s technology roadmap, but his stature in the industry would prove invaluable in building its cell design team.

As the team grew, a base of operations was required. A project office was set up on Gamla Brogatan in Stockholm.

The small business development team joined forces with the company’s cell designers to put together IKEA desks.

The team started to put together what would become Northvolt’s masterplan. A company launch date was set for March 2017.

Part 3: Coming Out of Stealth Mode

On March 7, 2017, Northvolt announced its plans to the outside world. The response was immediate.

The Northvolt mission: establish a European supply chain of batteries, beginning with Europe’s largest battery cell factory with annual production of 40 GWh.

Central to the vision would be clean energy, recycling and sustainable processes – all geared to ensure that the gigafactory would produce the world’s greenest battery.

At launch, Peter attempted to visualize the factory’s cell output using a bag of rice. It also illustrated the secret sauce to reducing cost: building at scale in combination with vertical integration of production processes.

The gigafactory would be built in one location (it was later split into two), produce only cylindrical cells (it now will produce two form factors) and the goal was to put the shovel in the ground within 18 months (it took 13 months).

The scale of the project was unprecedented. Prerequisites for success went beyond financing, and included: comprehensive environmental permitting, a top-notch site with access to large amounts of clean energy, and endorsement from both customers and suppliers.

Part 4: Building the Team

June 2017, Stockholm. Now 25 people strong, Northvolt has its first team picture taken.

People came from far and wide to join Northvolt.

From the earliest days Northvolt embraced bringing in graduate students through a summer internship program which continues to this day.

By mid-2020 Northvolt approached 700 people based in three countries and represented over 70 nationalities.

Part 5: Picking the Site

After the launch, the team put all its efforts into the number one priority: deciding upon a final location in the Nordics for the factory.

Emma Nehrenheim is Northvolt’s Chief Environmental Officer. She joined the company from ABB and has a background from the academic world, where she worked as a professor in Environmental Engineering.

Emma’s team was given the responsibility for the site selection process.

Those two locations: Skellefteå, 700 km north of Stockholm, and Västerås, 100 km west of Stockholm.

September 7, 2017. Peter presents the Northvolt project to the Västerås municipality board.

And to the Skellefteå municipality board a few days later.

On September 14, around 1000 people attended a public consultation in Skellefteå as a part of the environmental permitting process – probably a new Swedish record.

Hosted at Northvolt offices in Stockholm, the press conference was attended by national and international press, the mayors of Västerås and Skellefteå, and the Swedish Minister of Enterprise.

In the end, a split set up proved to be the best solution. Something to which both city mayors and the Swedish Minister of Enterprise seemed to agree with.

Part 6: Europe Gets Behind Northvolt

Northvolt started to engage with industrial companies around the opportunity to invest in the company to enable the establishment of Northvolt Labs. The interest was high, but the team soon realized that lead times would prove to be longer than first expected.

In September 2017, Northvolt made a significant breakthrough – securing its first industrial partner in Swedish-Swiss technology company ABB.

Wind power leader Vestas partnered with Northvolt to collaborate on lithium-ion battery platforms for its power solutions.

Scania and Northvolt also announced a partnership for development and commercialization of battery cell technology for heavy commercial vehicles.

Siemens joined the mission to digitalize the factory design process and with the goal of making Northvolt its preferred supplier of batteries.

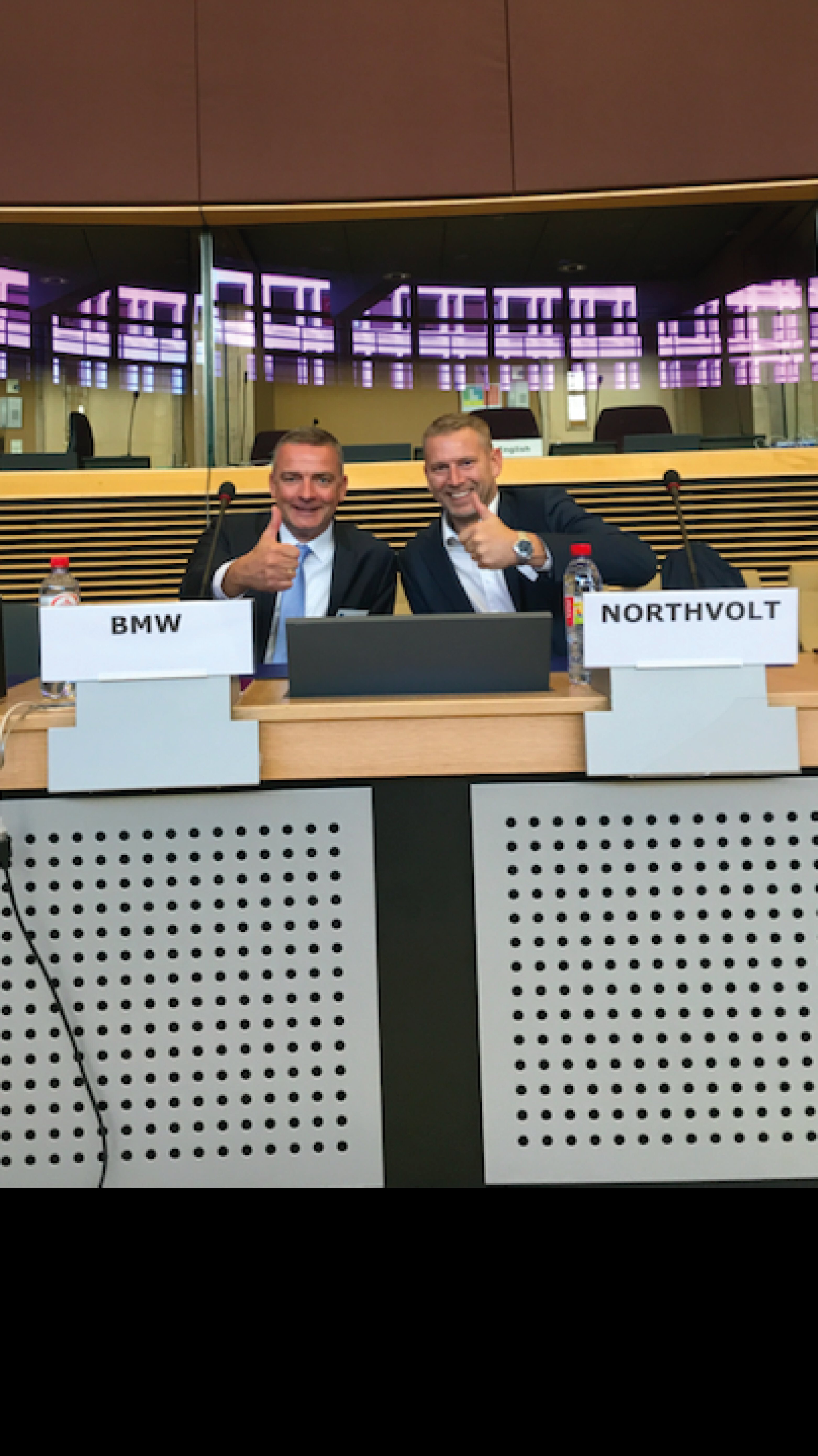

Another milestone was met when world-leading automaker BMW partnered with Northvolt.

The Northvolt Battery Systems team delivered the company’s first product in August 2018.

As batteries grew as a political issue, Northvolt did not go unnoticed by European political actors. Just as support from the European industry was crucial, so was political backing.

In February 2018, the European Investment Bank approved a loan for the establishment of Northvolt Labs.

Support from the Swedish Energy Agency also played a key role, with a grant of €13.6 million to support the establishment of Northvolt Labs.

With all the pieces in place, Northvolt sent out an invitation for the groundbreaking of Northvolt Labs in Västerås.

An electrified scooptram from Epiroc broke ground in Västerås.

The groundbreaking was attended by Vice President Maroš Šefčovič of the European Commission, Swedish Minister of Enterprise, Mikael Damberg, and Vice President of the EIB, Andrew McDowell, and marked an important step towards establishing the European value chain for batteries.

Part 7: Northvolt Labs

Northvolt Labs hosts a demo manufacturing line used to qualify and industrialize products and processes together with customers. It is a 19,000 square meter building with an annual production capacity of over 350 MWh.

Targeting construction commencing in spring 2018 and start of production in 2019, the timeframe was tight.

In the background to construction of Northvolt Labs, an R&D facility was established just across the street in ABB’s facilities.

Northvolt R&D plays a crucial role early development of cell products.

Using the R&D line, Northvolt produced its first prismatic cell in early 2019.

Cylindrical 2170 cells were first produced at the R&D facility in January 2020.

By December 2019, Northvolt Labs was online and producing cells – an important milestone considering upcoming customer deliveries.

Through summer 2020, Northvolt Labs continued to deliver cell samples to customers and expanded its head count to around 200.

Part 8: Northvolt Ett

At the heart of Northvolt is Northvolt Ett. Unique to its design, Northvolt Ett hosts active material preparation and recycling capacities, alongside cell assembly, and auxiliary processes.

To be developed as a phased build, the first phase of Northvolt Ett will be operational in 2021. Fully built, the factory will be one of the largest in the world – producing 40 GWh per year.

From mine to product, the battery industry typically involves a long supply chain and multiple independent players.

Northvolt will do things differently – integrating most of the supply chain in-house, whilst also adding additional capacities to extend its capabilities.

On June 7, 2018, Northvolt received an environmental permit for the first phase of the establishment. Ground preparations commenced the very next day.

Northvolt employees visited Skellefteå during summer 2018 to get acquainted with the site.

Carl-Erik Lagercrantz documenting the 500,000 square meter site that hosts the first part of the factory.

In June 2019, as ground preparations concluded, Northvolt completed an equity capital raise of $1 billion for the development of Northvolt Ett. Key investors included Goldman Sachs and the Volkswagen Group.

By this point in time, Northvolt had secured supply agreements amounting to a combined order value of over $13 billion through 2030.

The following year, in July 2020, Northvolt signed a debt raise of $1.6 billion – financing which would secure further development of Northvolt Ett, by this time construction was well advanced and the project remains on track for start of production in 2021.

Northvolt Ett has even become something of a local visitor attraction.

Part 9: The World's Greenest Battery

Northvolt’s mission is to build the world’s greenest battery with a minimal carbon footprint.

Northvolt’s commitment to sustainability encompasses sourcing of raw materials, production, transportation of goods, and novel recycling technologies.

Use of clean energy provides a foundation to securing a low carbon footprint to Northvolt batteries.

The amount of fossil free energy in a grid determines its carbon intensity.

A lithium ion battery requires around 109 kWh per kWh produced. Most of this is required for production. Where we produce batteries therefore makes a huge difference in the carbon footprint of an electric vehicle.

In December 2019, Northvolt launched its recycling program – Revolt.

Revolt technologies would be key to Northvolt reaching its goal of 50% recycled material in all new cells by 2030.

Through late summer 2020, a pilot recycling plant was established alongside Northvolt Labs, in Västerås, Sweden.

Part 10: Northvolt Battery Systems

Alongside cell manufacturing, development of industrial and grid battery systems is an integral part of Northvolt's strategic offering.

Northvolt Battery Systems was established in Gdańsk, Poland, in October 2018 for industrialization and assembly of battery modules and complete solutions.

The facility receives cells and assembles them into modules and larger battery system products for Northvolt's industrial and grid markets.

By fall 2019, the facility was well-established in terms of capacities and staffing.

The facility is heavily integrated with the Battery Systems team based in Stockholm, responsible for system design and development.

Back in Stockholm, Battery Systems moved into a new office in Liljeholmen in summer 2019, alongside a new workshop for prototype development.

Northvolt development of battery systems for Epiroc's emerging fleet of electrified mining machines occupies a large share of the work at Battery Systems.

Through 2019 the Epiroc program ramped up with trials of Northvolt-enabled electric machines in a commercial mine in Kittilä, Finland.

With more systems being deployed through 2019 and into 2020, in-field support and maintenance became key and an After Market team was established.

Development of other industrial and grid battery energy storage systems have also been points of focus.

In May 2020, Northvolt launched a mobile energy storage solution – Voltpack Mobile System.

Shipments are flowing from Battery Systems as demand and production capacity ramps up.